PLC Programing

As the Authorized System Integrator of OMRON, DELTA, and MITSUBISHI, a trusted and well-known brand in automation industry, There are many projects we have done using those PLC brands to automate industrial machine, such as :

1. Injection blowing bottle

2. Filling machine

3. Washer galoon machine

4. Extruder machine

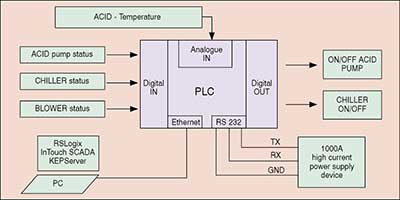

Here, we have one of our customers, PT. Ajinomoto Indonesia (Mojokerto plant) which had a need in controlling valves automatically at the utility area as the center of water supply and other materials to many different production line from PLC.

Problems : as this company has more than 10 valves to be controlled by PLC, the PLC will be performing slower in its operation and will affect the whole operation water supply system.

Objectives : Making the valves operates automatically without affecting other operation in PLC CPU (without getting slower)

Solution : After analyzing the whole process of water supply system in this company, our engineers decided to install PID card (LCB) in CPU PLC to avoid the slower response of PLC. LCB, Loop Control Board, is a special card in PLC Line up product which has the function of controlling PID. So, in Ajinomoto, it will have about 50 counting process with PID control to manage automatic valve in order to stabilize the water level.

Result : the systems either controlled by PID and without PID are able to run very well without even adding the cycle time in PLC.