Description

Innovation without growing pains

As a modern machine manufacturer you need to continuously increase the intelligence and flexibility of your product to remain competitive. But you also need to be absolutely certain that it all works perfectly, first time, every time.

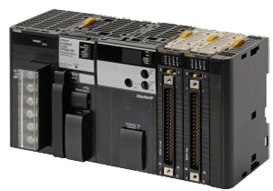

The Omron PLC CJ2 SERIES is the result of years of experience as market leader in the field of modular controllers and represents a logical next step in controller design. It offers greater performance and faster I/O response as well as extreme scalability – so you will only need one family. In addition, programming, debugging and networking are faster and easier.

Welcome to the new CJ2 Family: built to give you innovation without growing pains.