Delta PLC Programming

With over 25 years experiences in industrial automation, we are chosen as an authorized system integrator of some automation brands such as OMRON, DELTA, and MITSUBISHI in Indonesia. We have done several projects under those brands for many local and multinational companies. Our experts are trained professionally by our principal to operate and integrate all factory automation parts and build the industrial system that meet their goals in achieving cost savings and production/logistics efficiency and optimization.

DELTA PLC is getting more popular in many industries nowadays. Imported machines for plastics industry, textile industry, wood industry, packaging industry, many more are well-known with DELTA automated system. They use DELTA brand for PLC, Inverter, HMI, Servo, Power Supply, etc.

What are the benefits of choosing PLC DELTA for your system?

- Software is free to download from DELTA Website and similar to other software.

- Good for budgeted investment as the price of hardware is cheaper than other brands.

- Complete function in whole system such as complete set of PLC cards, Inverter applications, varies servo functions, HMI, etc.

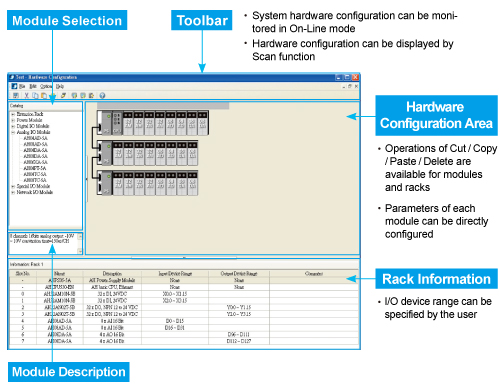

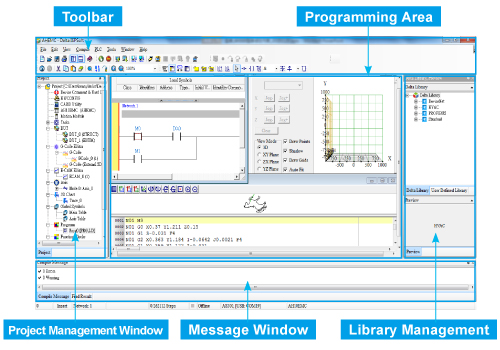

The Delta PLC Software is called as ISP Software. Here’s some looks of the software:

When you surfing more on this software, you will find out that this program is similar to MITSUBISHI GX Works. So, for those who familiar on GX Works, will not have any complicated issues, and able to do simple troubleshooting on this. In addition, you can get the hardware with cheaper price compared to other brand.

PLC or Programmable Logic Controllers offer many use that includes hardware configuration and network configuration. PLC can be used for motion control such through offer high speed stable connection. PLC can be setup as a series programmable logic controllers using DVP series programmble logic (PLC).

Our engineers have done several projects using DELTA hardware. If you need a PLC programmer with project management that uses development tool and are familiar with programing languages, programmable logic controllers (PLC), and controllers PLC system, please do not hesitate to contact us. Our expertise also involves in creating function blocks within the PLC control system. We use communication protocols connecting DELTA PLC through network configuration.

Recently, one of biggest company in Indonesia started their F&B industry and they built their new factory under DELTA systems. Starting from PLC to SCADA with DELTA Brand and work effectively. Apart from there, we have exposed to many different industries and applications which can help to assist you in fulfilling your automation gap / needs.

Related Blog

- AGV (Automated Guided Vehicles)

- Rotary Clipper

- Rekomendasi Relay Omron Terlaris untuk Penggunaan Umum

- Trik Membedakan Limit Switch Omron Asli dan Palsu

- Cara Kerja Relay OMRON Beserta Spesifikasi dan Fungsinya

- Mesin untuk Industri yang Harus Dimiliki Beserta Kegunaanya

- Mengetahui Cara Kerja Circuit Breaker Lebih Jauh

- Cara Efisiensi Distribusi Listrik pada Bangunan

- Slim Relay Omron, Inovasi Panel Control yang Hemat Ruang 50%

- Omron Sysmac Studio, Software Pilihan untuk Industri Anda

- Seluk Beluk Relay OMRON My-Gs

- Tampilan Asli Produk Timer H3CR OMRON

- Mengenal Building Automation System

- Pengantar Circuit Breaker: Fungsi dan Prinsip Kerjanya

- Sensor: Penjelasan, Cara Kerja, Jenis, dan Penerapannya

- Power Supply dalam Elektronik: Pengertian, Fungsi dan Proses Kerjanya

- Mengenal Lebih Dalam: Limit Switch dan Prinsip Kerjanya

- Linear dan Rotary Actuator, Apa Saja Perbedaannya?

- Mengenal Temperature Controller dan Cara Kerjanya

- Mengenal Perbedaan Saklar dengan Relay

- Penerapan Sistem Monitoring Energi dalam Menghemat Biaya Operasional Industri

- 8 Manfaat Sistem Monitoring Energi untuk Industri

- Cara Memilih Sistem Monitoring Energi yang Tepat untuk Bisnis Anda

- 10 Alasan Sistem Monitoring Energi Penting untuk Industri Manufaktur

- Cara Kerja Sistem Monitoring Energi untuk Meningkatkan Efisiensi Energi

- Delta PLC Programming